UV-Curable Low Surface Energy Coatings for Fouling Release and Anti-Graffiti Applications (RFT-254)

Invention Summary

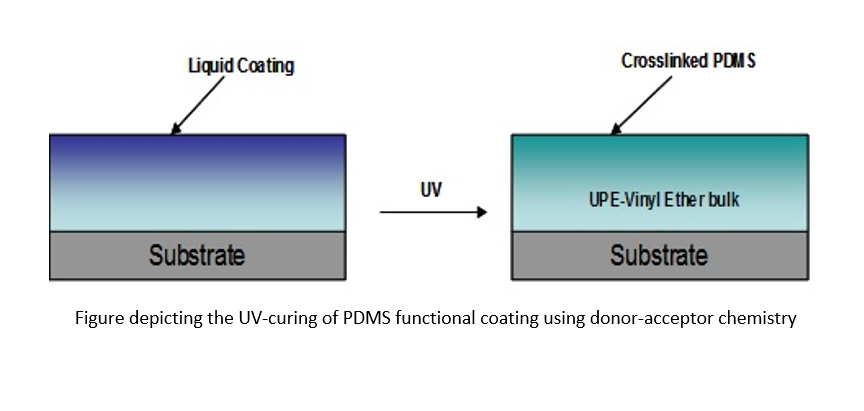

In the current market, there are several applications for low surface energy and UV curable coatings. Scientists at NDSU have developed a novel polyester composition that combines the two properties. The composition contains a modified siloxane backbone blended with co-reactants, diluents and photo-initiators. The mixing process is solvent-free and the composition can be crosslinked within a few minutes. The mixture can be cured using either visible or ultraviolet (UV) light. The modified backbone can be blended with different co-reactants, the most successful combination in the lab testing was - a monohydroxy, a telechelic, and a dihydroxy terminated PDMS UV-cured with triethyleneglycol divinylether. These coatings are beneficial in a variety of applications such as marine ship hulls, anti-graffiti surfaces, release coatings, and protective wood coatings with easily cleanable surfaces.

Benefits

- Coatings are solvent, water, and acrylate free

- Low surface energy

- Low manufacturing costs

- Resistant to Oxygen inhibition

- Eliminates health hazards associated with acrylates

- Low levels of siloxane

- Customizable with different diluents

Phase of Development

This technology has successfully completed laboratory testing with reproducible results.

Applications

Immediate applications include, but not limited to:

- Shipyards

- Paints

- Wood coatings

- Civil Infrastructure

- Packaging industry – electronics, food, paper, etc.

Patents

This technology is the subject of US Issued Patent No. 8,703,838 and is available for licensing/partnering opportunities.

Contact

NDSU Research Foundation

info@ndsurf.org

(701)231-8173

NDSURF Tech Key

RFT, 254, RFT254

Inquire about this technology >