Electrospinning Process for Continuous High-Volume Silicon Micro- and Nano-Wire Production (RFT-311)

Invention Summary

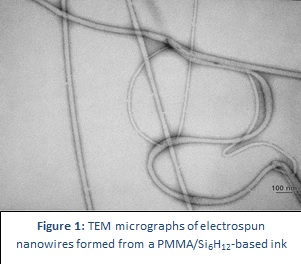

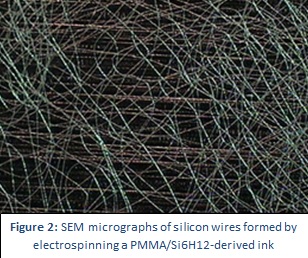

Scientists at North Dakota State University (NDSU) have developed a process for continuous high-volume production of silicon micro- and nano-wires based on electrospinning. The technology is based on the ability to use liquid silane as a starting material, so the length of the wires is essentially unlimited. The wires can be produced with a variety of polymers, metal particles, and silane variations to generate a range of properties and capabilities. Potential applications include composite materials, electronic devices, sensors, photodetectors, batteries, ultracapacitors, and photosensitive substrates. NDSU has developed synthetic routes to a liquid silicon precursor, cyclohexasilane (Si6H12), which is converted to silicon nanowires by electrospinning. Readily purified by distillation, the liquid nature of Si6H12 allows the development of a high-volume electrospinning route for silicon nanowire production. Because the spun wires convert to amorphous silicon at relatively low temperatures, formation of excessive surface oxide and carbide phases can be avoided. Silicon nanowires can expand radially during cycling without fracturing.

Benefits

- Silicon materials have high energy densities and capacities

- Produce extremely long and continuous lengths of micro- or nano-wire, the diameter based on the electrospinning apparatus

- Small cross-section wires aren't subject to microstructural changes that often occur in larger silicon structures

Patents

This technology is the subject of the Issued US patent 9346966 and the Issued Japanese Patent 5889276 and is available for licensing/partnering opportunities.

Contact

NDSU Research Foundation

info(at)ndsurf(dot)org

(701)231-8173

NDSURF Tech Key

RFT, 311, RFT311

Inquire about this technology >