Lignin-Based Thermosets and Foams (RFT-542, 614)

Invention Summary

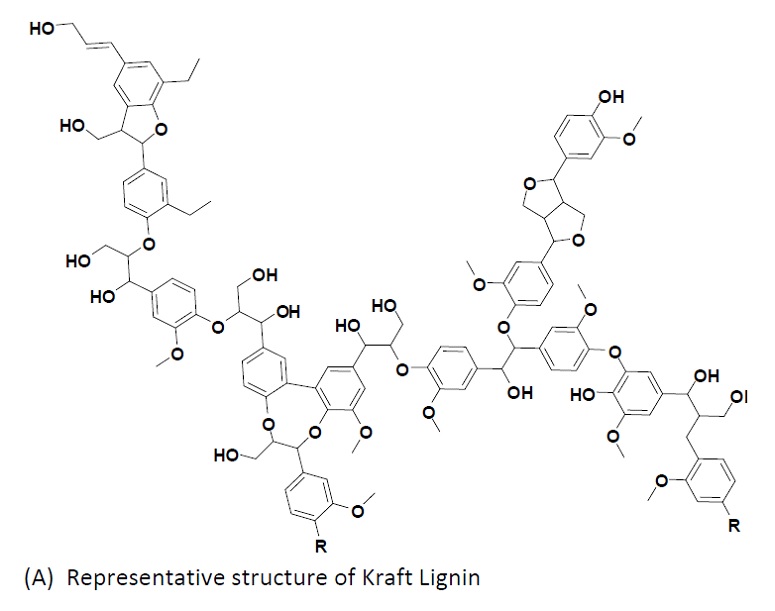

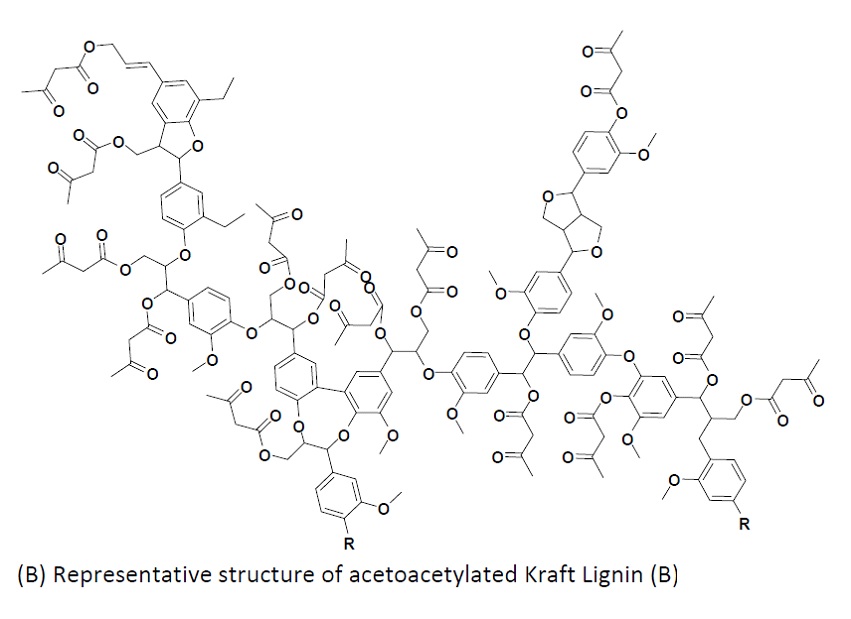

NDSU Researchers have developed a process to modify lignin, so as to produce acetoacetylated (AA-lignin) and methacrylated (MA-lignin) derivatives that are well suited for production of thermosets. This technology enables modification of full-sized lignin molecules, and depolymerized lignin subunits, by attaching reactive groups to some or all of the hydroxy groups. The derivatized lignin has lower viscosity than (for example) kraft lignin. This makes it easy to handle and to control crosslinking reactions and can be readily crosslinked to form thermosets through several different mechanisms, including reaction with amines, polyisocyanates, or melamine-formaldehyde resins.

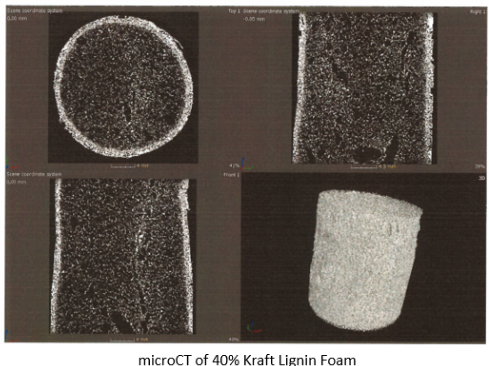

Additionally, this lignin-acetoacetate blend of Kraft resin has been used to synthesize novel lignin-based foams. These bio-based rigid foams can be synthesized without the use of hazardous polyisocyanates. The porosity and thermal stability of the foam is highly dependent of the amount of lignin used and can be tuned to meet specific applications. Furthermore, these sustainable foams exhibit comparable densities, compressive strengths, viscosity, insulation and other mechanical properties to that of commercially available structural foams.

Benefits

- Potential alternative source of phenolic and phenol-formaldehyde resins used in plywood, OSB, paper-based laminates, and other composites

- Enables multiple and flexible, value-added uses of native and modified lignin

- Lignin functionalization to produce AA- or MA-lignin may be performed in polyol solvents, eliminating the need for volatile solvents, or resulting problems associated with VOCs

- Production of AA-Lignin and MA-Lignin modifies the polyol solvent in the same way, and the polyol can be retained and integrates into the thermoset. This reduces cost, increases efficiency, and reduces waste.

- Broad range of potential applications wherever thermosets are used, including coatings, composites, and adhesives

- Sustainable and safe alternative to Polyurethane foams, without compromising the desired mechanical properties

- Instant, one step reaction makes it ideal for on-site use at room-temperature

- Rigid foams are suitable for a variety of applications; ranging from structural composite components, for insulation purposes, to use in the manufacture of everyday items.

Technology

The technology includes acetoacetylated and methacrylated functionalized lignin resin as well as rigid foam compositions, in addition to methods of making and curing the compositions.

Patents

This technology is the subject of the Issued US Patent 10,851,244 and the US continuation-in-part patent application (US 2021/0171720). The portfolio is available for licensing/partnering opportunities.

Contact

NDSU Research Foundation

info(at)ndsurf(dot)org

(701) 231-8173

NDSURF Tech Key

RFT,542,614,RFT542,RFT614

Inquire about this technology >