Compostable and Biodegradable Soy-Based Plastics (RFT-597)

Invention Summary

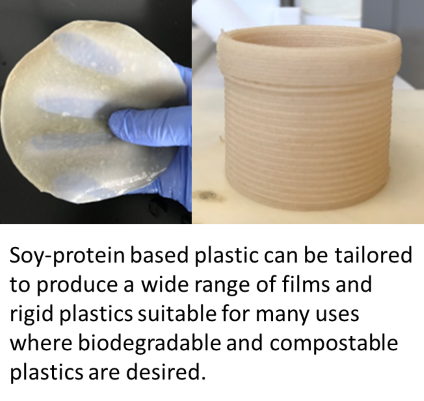

Researchers at NDSU have developed a biodegradable and compostable bio-plastic, which potentially eliminates the generation of long-lasting micro-plastics in products where this technology is used. This is a replacement for certain products that are made from high density polyethylene and polypropylene. The new plastic is an improved Soy Protein Isolate (SPI) based bioplastic formulation, optionally reinforced with cellulose nanofibers. The soy protein itself is stronger and more versatile than prior soy-based plastics for two reasons. First, the amine groups of this SPI plastic are modified to enable photo- or thermal- crosslinking, which produces polymers that are stronger, with strength that can be tailored by adjusting the amount of crosslinking. Second, the cellulose nanofiller provides reinforcement while maintaining the biodegradable and compostable benefits of this plastic. These performance improvements have been accomplished using only biodegradable ingredients, with the possible exception of the polymerization initiator. The resulting SPI-based bio-plastics formulation exhibits greatly improved physical properties as compared to other soy protein bioplastics, and creates an opportunity to replace certain applications of petroleum-based plastics where a fully compostable and biodegradable plastic is desired.

Benefits

- Biodegradable and compostable, but durable under normal storage and use conditions.

- SPI plastics, including those reinforced with nanocellulose, produce no microplastics, degrading in the environment to natural amino acids and sugars.

- Improved tensile strength, water resistance and flexibility as compared with prior soy-protein plastics.

- Improved processability and product rheology so that material can be 3D printed, extruded, casted, etc., at room temperature.

- Compatible with traditional plastic manufacturing methods such as injection molding, extrusion and 3D printing.

Applications

- Manufacturing items in:

a. Packaging industry, storage boxes / containers

b. foodservice products, toys, decorations

- Single-Use Plastics

- Agriculture and horticulture, including products designed for eventual biodegradation, such as nursery pots and root wraps, hay bale wraps, mulching films, etc.

- 3D printing resin

Stage of Development

This technology has successfully completed laboratory testing.

Patents

This patent is issued in the US, 11,739,216, and is available for licensing/partnering opportunities.

Contact

NDSU Research Foundation

info(at)ndsurf(dot)org

(701)231-8173

NDSURF Tech Key

RFT, 597, RFT597

Inquire about this technology >