Additive Manufacturing System Incorporated with Artificial Intelligence (RFT-635)

Invention Summary

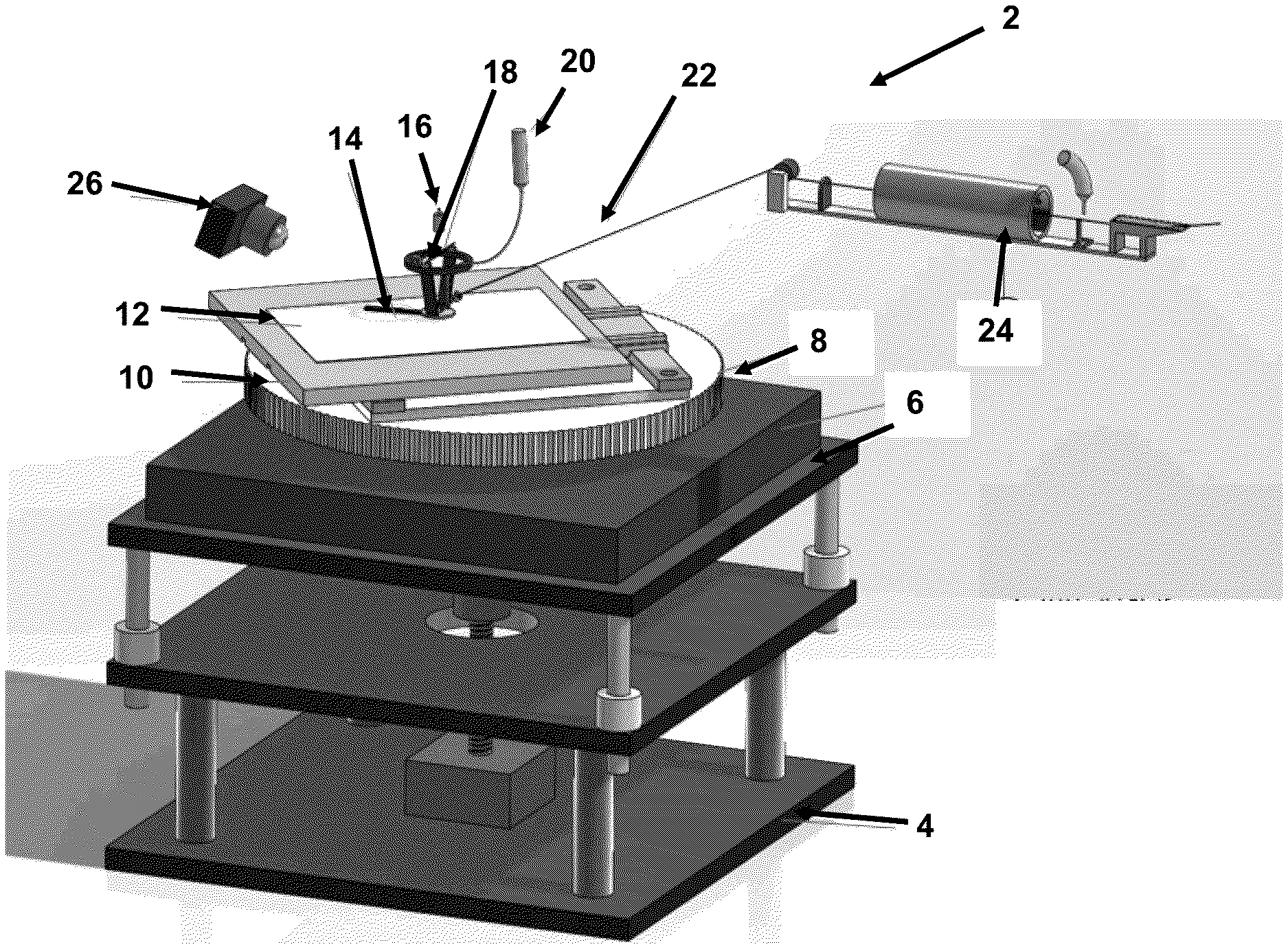

This patent introduces an advanced additive manufacturing system integrating continuous carbon fiber reinforcement with artificial intelligence. The system uses prepreg fibers impregnated with resin, partially cured before entering the printer. The fibers are coated with resin during printing, ensuring a high fiber volume fraction. AI monitors and adjusts print parameters in real-time, ensuring optimal adhesion, dimensional accuracy, and mechanical properties. The system also utilizes ultrasonic vibrations to reduce voids and improve resin dispersion, enhancing print quality.

Benefits

- Improved Mechanical Properties: Enhanced strength and durability through continuous carbon fiber reinforcement.

- Real-Time Monitoring: AI ensures continuous monitoring, reducing print failures and waste.

- Dimensional Accuracy: The system corrects errors due to post-curing and ensures precise dimensions.

- Efficient Resin Use: Optimized resin application and ultrasonic dispersion minimize material waste.

Applications

- Aerospace: Lightweight, high-strength parts for aircraft and spacecraft.

- Automotive: Stronger, lighter components for electric vehicles and high-performance cars.

- Medical Devices: Durable and customized prosthetics and implants.

- Renewable Energy: Components for wind turbines and other renewable energy equipment.

Inquire about this technology >