CURABLE COATING COMPOSITIONS HAVING SUPERHYDROPHOBIC, ANTI-ICING, AND ANTI-CORROSION PROPERTIES (RFT 650)

Invention Summary

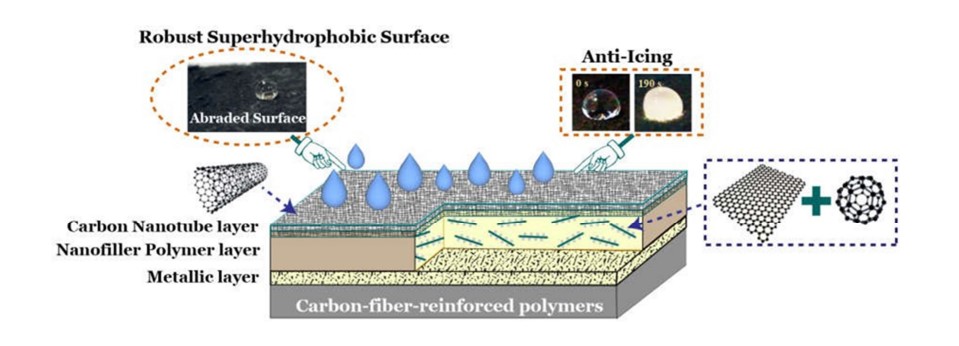

Carbon fiber reinforced polymers (CFRPs) are popular in aerospace, automotive, and marine industries due to their exceptional strength-to-weight ratio and corrosion resistance. This technology features a robust duplex coating composition applied to metallic CFRP surfaces. It comprises two main layers: 1. A base layer with epoxy resin reinforced by graphene nanoplatelets (GNPs) and fullerene-C60 nanofillers; 2. A top layer of carbon nanotubes (CNTs) for enhanced properties. This system effectively seals the pores and defects typical of metallic coatings, significantly improving electrical conductivity, mechanical resilience, anti-icing, and superhydrophobic properties.

Benefits

- Increased Electrical Conductivity: CNTs provide high conductivity.

- Superior Water Repellency: The CNT layer creates a superhydrophobic surface.

- Enhanced Anti-Icing: Delayed freezing times and reduced ice formation.

- Mechanical Durability: High resistance to abrasion and external damage due to GNP and fullerene reinforcement.

- Corrosion Resistance: The hybrid nanofiller provides long-term protective qualities even under harsh conditions.

Applications

- Aerospace components to prevent lightening strike damage

- Marine equipment requiring anti-corrosive, anti-icing surfaces

- Automotive parts for superior mechanical and weather-resistance performance

Patent

This technology has a U.S. Patent Pending US20240124716 A1 and is available for licensing/partnering opportunities.

Contact

NDSU Research Foundation

info(at)ndsurf(dot)org

(701) 231-8173

NDSURF Tech Key

RFT, 650, RFT650

Inquire about this technology >