High Temperature Corrosion Resistant Organic-Inorganic Hybrid Coating (RFT-680)

Invention Summary

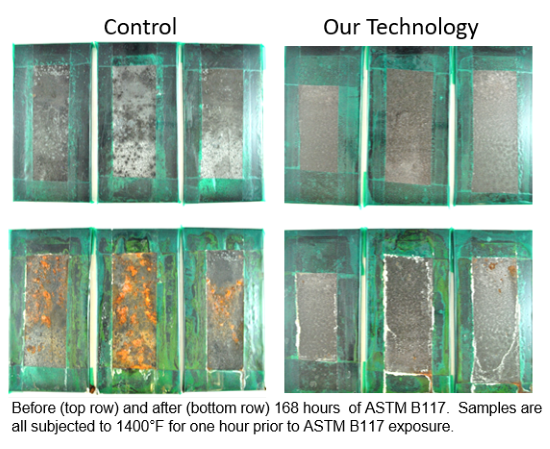

In industries requiring high-temperature protection, such as crude oil transportation, pipeline insulation, and exhaust stacks, conventional organic coatings fall short due to their limited heat resistance, degrading above 750 degrees Fahrenheit. This innovation presents a hybrid coating developed by converting an ambient-cured polysiloxane film into a silicon oxycarbide (SiOC) glassy film through open-to-air-on-substrate pyrolysis. This novel process incorporates high-temperature iron corrosion products, forming coherent, adherent, and crack-free coating. The hybrid coatings have been rigorously tested and characterized for barrier properties, surface morphology, and chemical composition at temperatures up to 1400 degrees Fahrenheit.

Benefits

- High-Temperature Resistance: Withstands temperatures up to 1400 degrees Fahrenheit

- Corrosion Protection: Provides excellent corrosion resistance at both ambient and elevated temperatures

- Crack-Free Coatings: Ensures the formation of uniform, crack-free films on metallic substances

- Versatile Application: Easily applicable to large surface areas, combining the advantages of organic coatings' flexibility with inorganic coatings' durability

Applications

- Industrial Pipelines-Ideal for protecting pipelines carrying crude oil or other high-temperature substances

- Marine Engineering-Useful for coating exhaust stacks of large ships to prevent heat-induced corrosion

- Automotive and Aerospace-Suitable for components exposed to extreme heat, such as engine parts and aerospace components

- Energy Sector-Applicable to equipment in energy storage and conversion systems requiring high-temperature endurance

Patent

This technology has a U.S. Patent Pending and is available for licensing/partnering opportunities.

Contact

NDSU Research Foundation

info(at)ndsurf(dot)org

(701) 231-8173

NDSURF Tech Key

RFT, 680, RFT680

Inquire about this technology >